CRAFTSMANSHIP

CRAFTSMANSHIP

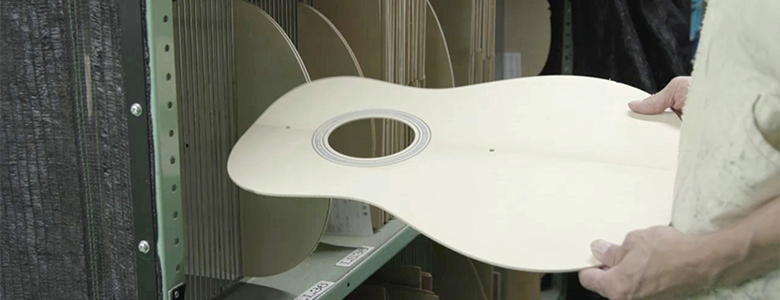

Even with advanced manufacturing techniques, it isn’t possible to automate the production of great guitars. The complexity of the task, combined with the need for constant awareness of the materials being used and the ability to adjust for minute variations, means that there is no substitute for the skill and sensitivity of experienced craftspeople.

-

디자인을 훌륭한 기타로 구현

디자인 대로 훌륭한 악기를 만드는 것은 쉽지 않은 작업입니다. 기술 도면은 악기가 의도한 톤이나 원하는 특성과 소리를 구현하는 데 필요한 제작 방식을 전달할 수 없습니다. 새 기타 제작이 시작되기 전, 적절한 생산 공정 개발을 위해 디자이너의 계획과 의도를 공장 장인과 상의합니다. 모든 기타가 다르기 때문에, 각 기타에 이상적인 생산 방식과 작업 흐름을 고안하는 것이 매우 중요합니다.

-

철저한 작업

가끔 '무리해서' 일하는 것이 가능한 모든 상황에서 일관성 있게 원하는 품질 구현을 보장하는 유일한 방법이 되기도 합니다. Yamaha는 대부분 제조 디테일을 극한까지 추진하는데, 결과물을 보면 그럴 만한 가치가 있습니다. 마감 작업 전 제조 공정 초기에 어쿠스틱 기타 바디와 넥을 미리 맞추는 Yamaha의 공정이 한 예시입니다. 넥과 바디의 조인트 품질이 악기의 톤과 반응을 최대화하는 데 중요한 역할을 한다는 점은 경험을 통해 알 수 있습니다. 즉, 넥과 바디가 직접 접촉하는 부분이 완벽하게 맞춰져야 합니다. 넥과 바디를 한 쌍으로 제작하고 마감하는 데서 비롯되는 조절과 일관성 수준은 더 많은 노력을 기울일 가치가 있습니다.

-

기계의 정밀성과 인간 기술의 이상적 결합

기계에 가장 적합한 작업이 있습니다. 특히 극한의 정밀성과 반복 작업이 요구되는 작업이 여기에 해당됩니다. 예를 들어, 핑거보드 프렛 슬롯 절단 작업은 컴퓨터가 제어하는 기계의 정밀한 작업이 필요한 중요 작업입니다. 하지만 기타리스트가 원하는 바를 제대로 충족하는 악기를 제공하려면 개별적인 관심과 융통성이 요구됩니다. 여기에서 Yamaha 장인의 기술과 경험이 빛납니다.

-

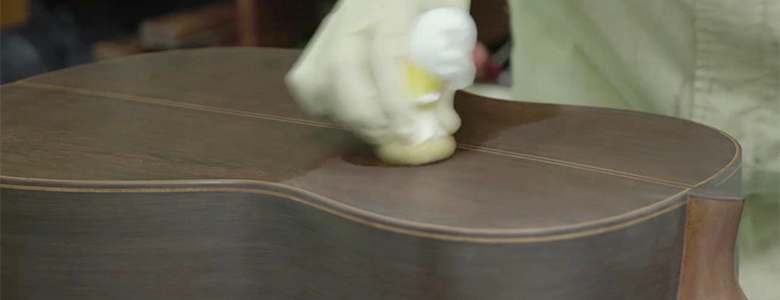

마무리 손질

Yamaha는 모든 기타와 베이스가 공장에서 최적의 연주 조건을 유지하도록 노력합니다. 일부 연주자는 개인의 연주 스타일에 맞는 간단한 조정을 원하겠지만, 프렛 레벨링과 마무리 같은 중요 디테일은 공장에서 커스텀 매장으로 바로 넘어갑니다. 최적의 톤과 성능을 구현해야 할 경우 가장 주의를 기울여야 할 생산 단계는 최종 조립입니다. 부품을 적절히 배치하지 않거나 단단히 부착하지 않으면 사운드와 연주 성능이 모두 저하될 수 있으므로, 원활하고 효율적인 조립을 위해 조립 워크스테이션과 공정을 설계하고 정립하여 제작자가 완벽한 결과물을 만드는 데 온전히 집중할 수 있습니다.

-

도구 제작

기타 제작에 사용되는 도구 대부분은 목적에 맞게 수작업으로 만들어야 하며, 많은 도구들이 단일 모델에 맞게 특수 제작되므로 다른 기타에 사용할 수 없습니다. 기타 제작자의 일관성 있는 완벽한 악기 생산을 편리하게 해줄 도구와 지그 개발은 Yamaha의 장인정신에 대한 접근방식에서 중요한 요소이지만, 도구와 지그는 사용하면서 마모되어 제대로 맞춰지지 않을 수 있습니다. 따라서 항상 완벽한 작업 상태를 유지할 수 있도록 각별히 주의해야 합니다. 이는 전반적인 품질 관리에서 보이지 않지만 필수적인 부분입니다.

-

살아 있는 제작 공정

고급 기타 제작은 숙련된 장인의 기술에 의존하기 때문에, 미래에도 일관성 있고 꾸준한 품질을 보장하는 유일한 방법은 차세대 장인에게 노하우를 전수하는 것입니다. 이 기술 유형은 사람 간의 직접 견습을 통해서만 온전히 전달될 수 있기 때문에, Yamaha는 이 과정을 기타 제작 공정에 공식적으로 포함했습니다. 세월이 흐르면서 기타 제작자 팀에 변화가 있지만, Yamaha는 기타의 지속적 진화를 위해 기본 기술 및 과정 중에 개발되는 여러 혁신 기술이 전수될 수 있도록 노력합니다.

-

기타 제작 공정